1. How is sealing performance ensured?

Sealing is crucial when designing cold storage loading zones. A telescopic dock leveler installed inside the cold storage sliding door can drop directly to the bottom of the pit after the door closes, cutting off indoor-outdoor airflow and achieving a fully sealed loading position to reduce energy loss. Our dock shelters use chloroprene fiber curtains and steel protective frames for wind and rain resistance, while minimizing heat exchange.

2. How effective is the cold chain insulation?

For clients with stricter cold chain requirements, the system allows refrigerated trucks to park and then be accessed from inside the building through a specially designed pit. This approach minimizes temperature fluctuations inside the refrigerated compartment during loading and unloading.

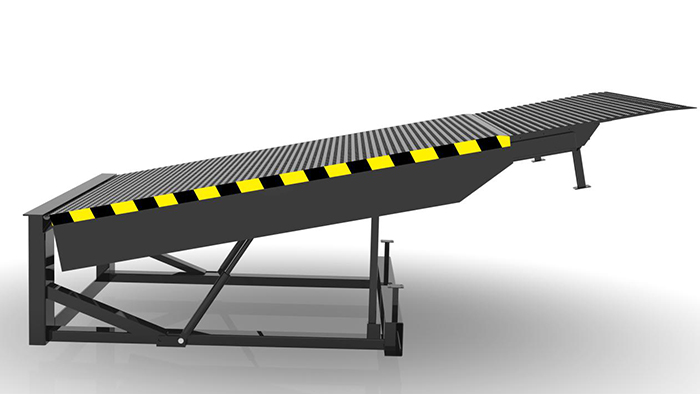

3. Is it compatible with different vehicle types and platform sizes?

We offer hydraulic dock levelers and telescopic dock levelers that can be integrated with insulated sectional doors and inflatable dock shelters, based on customer needs. The lifting height and telescopic reach (up to 1200 mm) of the tongue plate are fully adjustable. Even if the truck’s rear is fully loaded, a small overlap is sufficient to complete loading/unloading in one go, boosting operational efficiency.

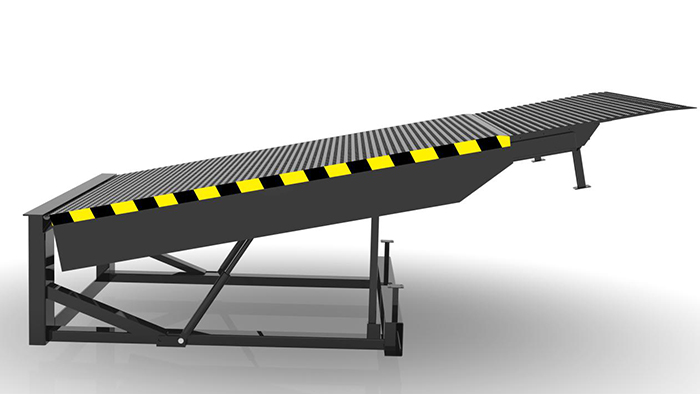

4. Is safety protection integrated into the system?

The dock leveler’s platform uses 8–10 C-shaped steel reinforcements to maintain surface flexibility and optimal support. Impact resistance is enhanced through a through-type maintenance support rod. The telescopic tongue features a dual 5° arch and smooth arc transitions to reduce the risk of cargo tipping due to forklift bumps.

5. How is speed balanced with stability?

Fastlink’s patented IoT control box ensures fast response times. The closed tubular hinge system increases contact area with the pin shaft, delivering stronger and more uniform force. Grease injection points ensure smooth movement and long-lasting mechanical performance, even under high-frequency operation.

6. Are maintenance costs manageable?

The maintenance-free design concept runs through the life cycle of the product. The inverted design of the loading platform cylinder effectively prevents dust from accumulating, leading to oil leakage of the cylinder seal and failure of the safety locking valve. Mechanical dock shelter is added with steel protection device to protect loading and unloading goods and door cover from collision during loading and unloading process; unique decompression design of sponge dock seal effectively reduces the friction between door seal and truck and prolongs the service life of the door seal; the surface material of inflatable seal is high quality neoprene fiber rubber material with high abrasion resistance and suppleness, and the service life of the door seal is more than 30,000 times.

7. Can it support intelligent park management?

- Fastlink’s self-developed Eye of Technology control system enables remote equipment monitoring through an IoT control box, integrating cloud-based order tracking with the control system.

- We've invested in an intelligent service management platform that offers features like real-time order tracking, one-click maintenance requests, and mobile customer feedback, delivering end-to-end service.

- Our IoT control box enables control box (protected by a national patent) allows for full system interconnectivity and shifting from passive to proactive service.

8. Are there verified use cases in real environments?

Fastlink’s dock leveler solutions have been verified in cold chain warehouses by industry leaders like Prologis, JD.com, and Hema. We also serve automotive clients such as Mercedes-Benz and BMW, meeting the high-frequency operational demands of auto parts logistics.

9. Does the company provide ongoing service?

- Fastlink maintains nationwide after-sales service centers, offering full-lifecycle support through a professional project management, installation, and after-sales team, ensuring faster response times than industry norms.

- The responsibility traceability system ensures all maintenance data is logged and accessible via our information management platform.

- We offer cost-effective service packages covering all consumables and repair items.

- Every Fastlink product and on-site service team is backed by third-party insurance, providing added peace of mind.

10. Are customizable upgrade solutions available?

Our full-process service system includes demand analysis, solution design, and manufacturing. Based on modular production, customers can select component specs, color schemes, and functional configurations, ensuring that personalized requirements are precisely met and quality is controlled from design through delivery.

Why Choose Fastlink?

√ National High-Tech Enterprise backed by 138 patented technologies

√ German Hennecke fully automatic door panel production + in-house R&D for total quality control

√ Trusted by leaders across industries: Prologis, JD.com, Mercedes-Benz, and more

√ A 3-in-1 delivery model: advanced equipment, intelligent systems, and full-lifecycle services