Pain Points in clean Rooms and Fastlink’s Innovative Solution

In high-cleanliness industries such as food, pharmaceuticals, and electronics, clean Rooms demand exceptional sealing performance, dust prevention efficiency, and rapid passage speed. Traditional industrial doors suffer from slow operation, dust accumulation, and high energy consumption. However, the Fastlink HSR-IPB Interior High Speed Rolling Shutter Door overcomes these challenges with its core technological advantages. Today, based on real-world test data, we’ll break down how this industrial door uses innovative solutions to safeguard efficient, clean, and safe production environments!

The Essential Requirement of Clean Rooms

1. High-Speed Operation: clean Rooms require industrial doors to open and close extremely quickly (typically ≤3 seconds) to minimize air exchange, reduce energy loss, and ensure smooth, frequent operation in high-traffic scenarios (e.g., pharmaceutical filling lines, electronics clean Rooms).

2. Ultimate Sealing: clean Rooms must block particles ≥0.3μm (meeting ISO 14644-1 standards), with door gaps ≤1mm to prevent contaminants like dust and insects from entering, ensuring production precision.

3. Safety & Durability: Doors at forklift passageways need impact resistance and multiple safety features to protect personnel and sensitive equipment.

Fastlink Interior High Speed Rolling Shutter Door’s "Five Game-Changing Features"

1. Lightning-Fast Operation:

Servo motor enables opening speeds up to 1.2m/s and closing speeds of 0.6–0.8m/s, drastically reducing wait times.

Variable-frequency control ensures smooth, quiet starts/stops, ideal for high-frequency use.

2. Dust-Tight Sealing:

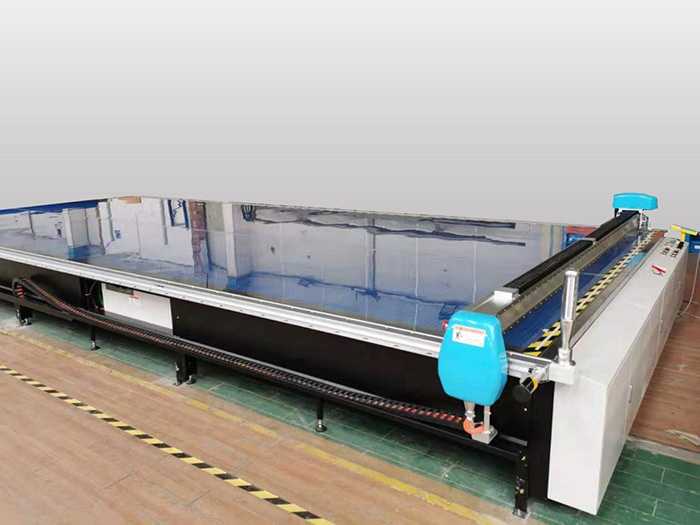

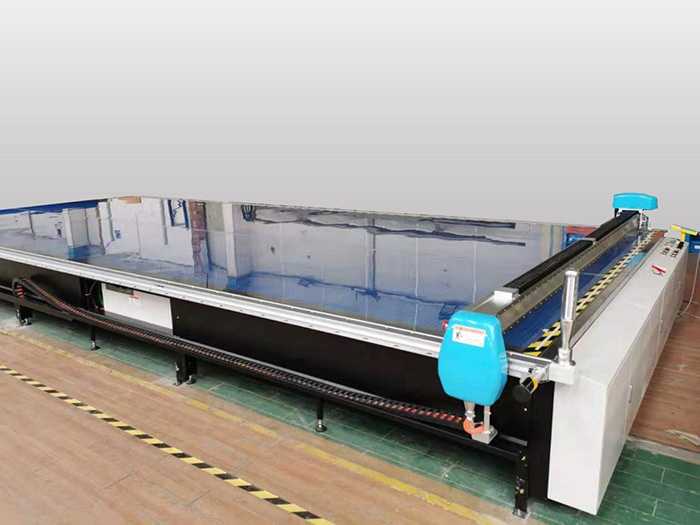

Curtains precision-cut (≤1mm error) with Swiss laser equipment.

Brush-embedded tracks block dust, insects, and airborne contaminants.

3. Collision Recovery:

High-precision, wear-resistant PVC curtain produced via automated systems.

Soft collision-resistant bottom edge auto-resets after impact, eliminating maintenance.

4. Comprehensive Safety:

Safety photoelectric sensors: Door reverses to full opening if obstructed.

Wireless airbag eliminates tangled cords, ensuring reliable anti-pinch protection.

Optional manual/auto motor and UPS backup power for fail-safe operation.

5. Smart Integration:

Fastlink’s proprietary control system consolidates multiple functions into one panel.

Built-in fire safety interface syncs with building systems (smoke detectors, sprinklers, alarms) for real-time protection.

Choose the Right Industrial Door to Boost Your Workshop Production!

Fastlink's Interior high speed rolling shutter door is not just a simple upgrade but a comprehensive innovation in terms of material, structure, and intelligence. Speed, sealing, durability, safety, and intelligence—these five advantages perfectly solve the pain points of clean workshops. If your workshop is still struggling with cleanliness issues, why not try the Fastlink industrial door?