12/6/2024

As an integral part of modern industrial and commercial buildings, sliding doors are usually used in factories, warehouses, and other places where large areas need to be opened and closed, and their stability is a crucial consideration in the design and use process, directly related to the use of safety and efficiency.

For large openings, the stability of the door body depends first on the structural design. The Fastlink insulated sliding door uses double-layer aluminum door panels with high-density polyurethane filled in the middle. The inner and outer metal door panels are overlapped during molding to effectively prevent the door panels from cracking, and are light and strong. At the same time, the thickness of the four-layer hinge ensures the fixing strength of the hinge screws. For openings wider than 5500mm, to enhance stability, reinforcing ribs are added to the inner side of the door body as a supporting structure to reduce deformation caused by the increase in span.

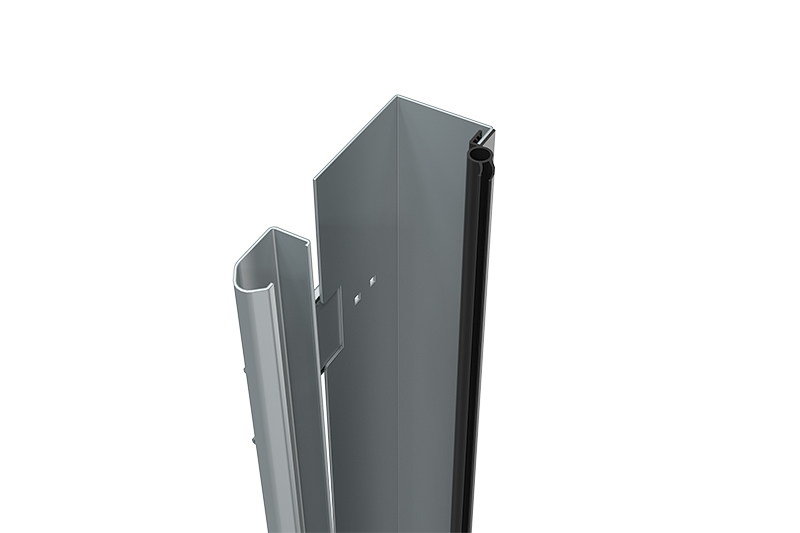

Track system

The design of the track system is also a key factor in ensuring the stability of large-span sliding doors. High-quality slide rails and roller systems can reduce friction and ensure the smooth and stable operation of the door. The unique C-shaped track design of Fastlink prevents the roller from falling out of the track, and the special folding design effectively enhances the wind resistance of the door. It is worth mentioning that the Fastlink track and auxiliary rail are connected by bolts, which is convenient for later maintenance and replacement and can effectively reduce the after-sales service cost.

Drive system

The choice of drive system also affects the stability of large-span sliding doors. The electric drive system uses a motor to drive a chain or wire rope to achieve the lifting and lowering of the door body. Fastlink uses an electronic limit motor, which has accurate upper and lower limit positioning, convenient debugging, and does not require climbing to the motor position for debugging. It has low operating noise and a high continuity rate.

Intelligent control system

In addition to hardware considerations, introducing intelligent control systems also provides a new solution for improving the stability of large-span sliding doors. The Fastlink intelligent control system can monitor the door's status in real-time. Once an abnormal situation (such as blocking, overload, etc.) is detected, it immediately stops operation and issues an alarm, effectively avoiding safety accidents. At the same time, these systems can also record information such as the number of times the door is used and the maintenance cycle, which is convenient for managers to conduct scientific management and scheduling.

It is worth mentioning that installation and maintenance are also important factors affecting the stability of large-span sliding doors. The professional installation team will formulate a reasonable installation plan based on the on-site situation to ensure that each operation step meets the specifications' requirements. Regular maintenance is also essential for subsequent use, including cleaning the track, checking the degree of roller wear, lubricating moving parts, etc. These are necessary measures to extend the door's service life and ensure stability.

The stability of large-span industrial doors is a comprehensive issue involving structural design, material selection, track system, drive mode, intelligent control, etc. Only by striving for excellence in every link can we ensure the door's safety and reliability in actual use.