But how can we know if the sectional door is insulated? Can we just distinguish them visually? Or is it hard to know?

Let's discuss some main indicators and explore why insulation is a worthwhile investment for your business facility.

Why Insulation Matters for Your Sectional Door

First, why bother checking if your sectional door is insulated or not? Is insulation that important in an industrial sectional door? Let’s understand together why insulation is so important for industrial applications:

- Energy Efficiency: A sectional door is a great and effective thermal barrier. They do a great job of blocking heat loss in the cold months and preventing excess heat from entering the room in the summer. Insulated sectional doors are a lifesaver for businesses that require climate-controlled environments, as they will undoubtedly save a great deal of money on heating and cooling costs.

- Noise Reduction: The insulation on the door panels minimizes external noise, making it a perfect space to work on your next big project. This is a big advantage for facilities that are located in a noisy industrial zone. This noise reduction not only reduces the noise from outside but also from inside.

- Protection for Stored Items: Extreme temperature fluctuations can affect the quality and lifespan of various industrial assets, such as raw materials, food and beverages, and even electronic and machinery materials, which are very sensitive to temperature. Insulation provides a protective layer to protect these valuable items.

How to Tell if Your Sectional Door is Insulated: Key Indicators

Are you ready to examine your industrial sectional door? Here are the most popular ways to test how well the door is insulated:

1. The "Knock" Test

Simply knock on a small area of the door. A hollow, tinny type sound will be heard from a non-insulated door, which does not offer much substance.

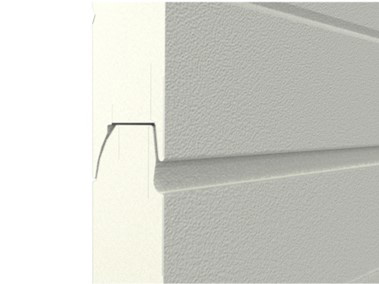

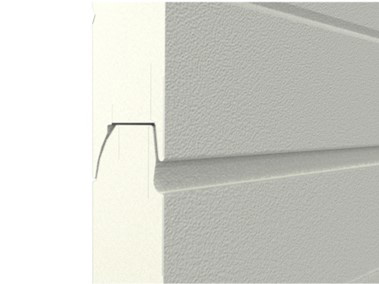

2. The Thickness and The "Sandwich" Construction

Insulated industrial doors are usually thicker than those without insulation because of their "sandwich” construction. One clear sign of insulation is the "sandwich” style of the door. An insulated sectional door will be made of 2 layers of steel or other material(the "skins"), with insulating foam (such as polyurethane or polystyrene) in between, and you may be able to see this foam if the door is open or there is any exposed edge. Whereas, a non-insulated door will be a single sheet of the same material on the inside.

3. The Temperature Differences

This method requires a bit of patience and a very hot or chilly day. Just touch the inside of your industrial door on the extreme weather day, if your door is insulated, the inside will feel close to the temperature inside your facility rather then the extreme outdoor temperature, if it is not insulated the inside of the door will feel similar to the temperature outside – cold in the winter, and hot in the summer.

4. The Manufacturer's Specifications

In the door’s manual, model number, or even original invoice that you received often lists whether the door is insulated and even retrofit information, and with the model number, you can often find detailed specs on the manufacturer’s website.

Sectional Doors vs. Roller Doors: Do They Offer The Same Insulation?

When choosing industrial doors, there are two common options: sectional and roller doors. They vary greatly in terms of design, insulation, and operation.

Sectional doors are created by having multiple horizontal panels hinged together that wrap around a roller, which then extends or lifts into the overhead space. This door design has multiple sections to protect insulation against outside winds deeply (and can create a "sandwich”-type group of panels filled with foam to achieve superior R-value and a good seal). This makes them highly preferred in facilities where temperature control is critical, such as cold storage or climate-controlled environments.

Industrial roller doors, on the other hand, are single, flexible curtains made of interlocking sections that coil around a barrel mounted above the door opening. While they are often valued for their simplicity, durability, and minimal overhead space requirements, their single-curtain design generally offers less opportunity for effective insulation compared to sectional doors. They are frequently used in standard warehouses or in locations where maximum thermal performance is not a main requirement.

Industrial Sectional Doors by Fastlink

As you can see, there are many types of sectional doors. Selecting the style that best suits you requires an understanding of your application’s requirements. Thankfully, we have various sectional doors available, including the insulated and the non-insulated ones.

Insulated Sectional Door

With features including insulation, wind resistance, anti-theft, sealing, safety, and intelligent control, insulated sectional doors are often used as logistical access doors in industrial buildings. The door panel is made up of several layers of panels that are filled with 100% fluorine-free imported Huntsman high-density polyurethane. The rollers on either side of the entrance, which are equipped with a dynamic balancing mechanism, move up and down along the guide rail, increasing the venue's efficiency and safety when people enter and exit. Cold chains, automotive facilities, semiconductor plants, food manufacturers, pharmaceutical factories, and logistics warehouses are examples of typical application industries.

Aluminum Single Sectional Door

A number of performance-enhancing features, such as wind resistance, anti-theft capabilities, sealing, and intelligent control, are available. With a rating of up to 700pa, it is lightweight and provides excellent wind resistance. We have put in place a variety of security measures to ensure safe and worry-free use in the logistical port of entry.

Insulated Sectional Door for Cold Storage

For any industrial building with cold storage needs, a special insulated sectional door is crucial, offering essential features like superior insulation, strong wind resistance, enhanced anti-theft capabilities, tight sealing, robust safety, and smart control. These doors achieve optimal temperature regulation through a segmented cold bridge design and multiple layers filled with 100% fluorine-free imported Huntsman high-density polyurethane. Their smooth operation, facilitated by dynamic balancing and corrosion-resistant hardware, ensures efficient and safe entry and exit, making them ideal for sectors like food processing, cold chain, pharmaceuticals, and cold climate building entrances. Their smooth operation, facilitated by dynamic balancing and corrosion-resistant hardware, ensures efficient and safe entry and exit, making them ideal for sectors like food processing, cold chain, pharmaceuticals, and cold climate building entrances.